Fab.com Sale going on now!

We are excited to announce that RamonaMetal has partnered with the amazing Fab.com for a seven day sale starting May 19th and ending May 26th. We will be offering amazing sale prices on several RamonaMetal products including the Airfoil Desk, Deco Crate, Deco Shelf and Aeromen. Check it out here.

We are excited to announce that RamonaMetal has partnered with the amazing Fab.com for a seven day sale starting May 19th and ending May 26th. We will be offering amazing sale prices on several RamonaMetal products including the Airfoil Desk, Deco Crate, Deco Shelf and Aeromen. Check it out here.

Airfoil Desk: From sketch to aluminum: Part II

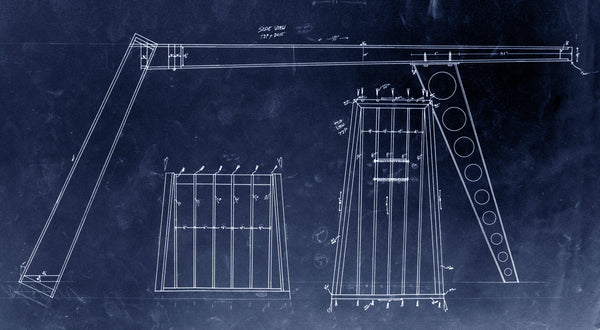

The next step in bringing the Airfoil Desk to fruition was to create a detailed drawing. This is one of the most important steps when we create a new product. We typically hand draw our detailed plans at a 1:1 or 1:2 scale on a white canvas mounted on our studio wall. Here we determine all the desk’s dimensions such as height, length and width. We also create detailed drawings of all the components that make up the desk such as the numerous wood parts and the aluminum support.

We plan early on how we can create a product that is easy and affordable to deliver. Nothing is more frustrating than purchasing a piece of furniture online and paying another $250+ for shipping! For the Airfoil desk we came up with a simple solution - hinge the base and tip together and ship the desk flat. With this configuration the desk requires a minimal amount of assembly but the shipping charges shrink to less than $100. A fair tradeoff to most customers.

- James Stumpf

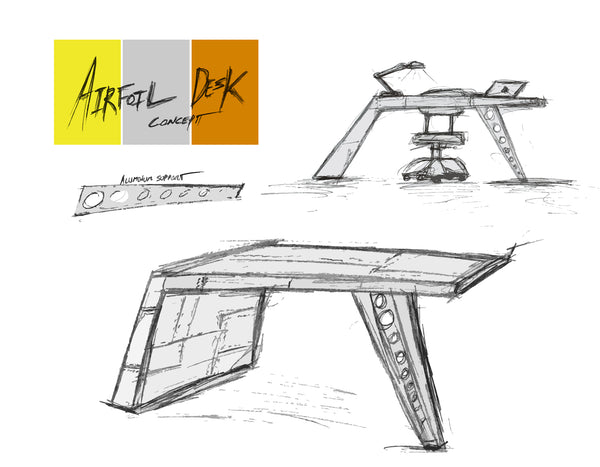

Airfoil Desk: From Sketch to Aluminum: Part I

The Airfoil Desk was something I envisioned building some time ago. I set out to build a desk that was incredibly simple but also incredibly industrial. I wanted to use metals and alloys not commonly used to build furniture today: aluminum, brass and copper. The desk looks massive at its base but tapers down to a fine point at its opposing edge. Above is a compilation of some of the early sketches made. This was the first step we took to create the Airfoil Desk.

- James Stumpf

Touch Of Modern Sale Going on Now!

We are excited to announce that RamonaMetal has partnered with the amazing TouchofModern.com for a five day sale starting September 2nd and ending September 7th. We will be offering amazing sale prices on several RamonaMetal products including the Airfoil Desk, the Deco Crate, the Deco Shelf and the Aeromen. Check it out HERE.

We are excited to announce that RamonaMetal has partnered with the amazing TouchofModern.com for a five day sale starting September 2nd and ending September 7th. We will be offering amazing sale prices on several RamonaMetal products including the Airfoil Desk, the Deco Crate, the Deco Shelf and the Aeromen. Check it out HERE.

Airfoil Desk: From sketch to aluminum: Part III

On our last post in this series, we described our detailed blueprint and how it was created. From that print, we will create a construction manual with detailed drawings, dimensions and instructions on how to build each part that makes up the Airfoil Desk. We will use this construction manual in the shop along with wood cutting jigs to create the wood core of the Airfoil Desk which later gets wrapped in metal. The desk has some challenging geometry so its absolutely critical that each part comes out perfectly on specification. If one part were improperly sized it would trigger a domino effect during assembly throwing each part out of alignment.

-James Stumpf